study

The advantages of software driven intelligent depowdering – use case Enerbine

The effect of SPR-Pathfinder® when removing powder from heat exchangers.

DOWNLOAD

KONTAKT

MARKETING@SOLUKON.DEINTRODUCTION

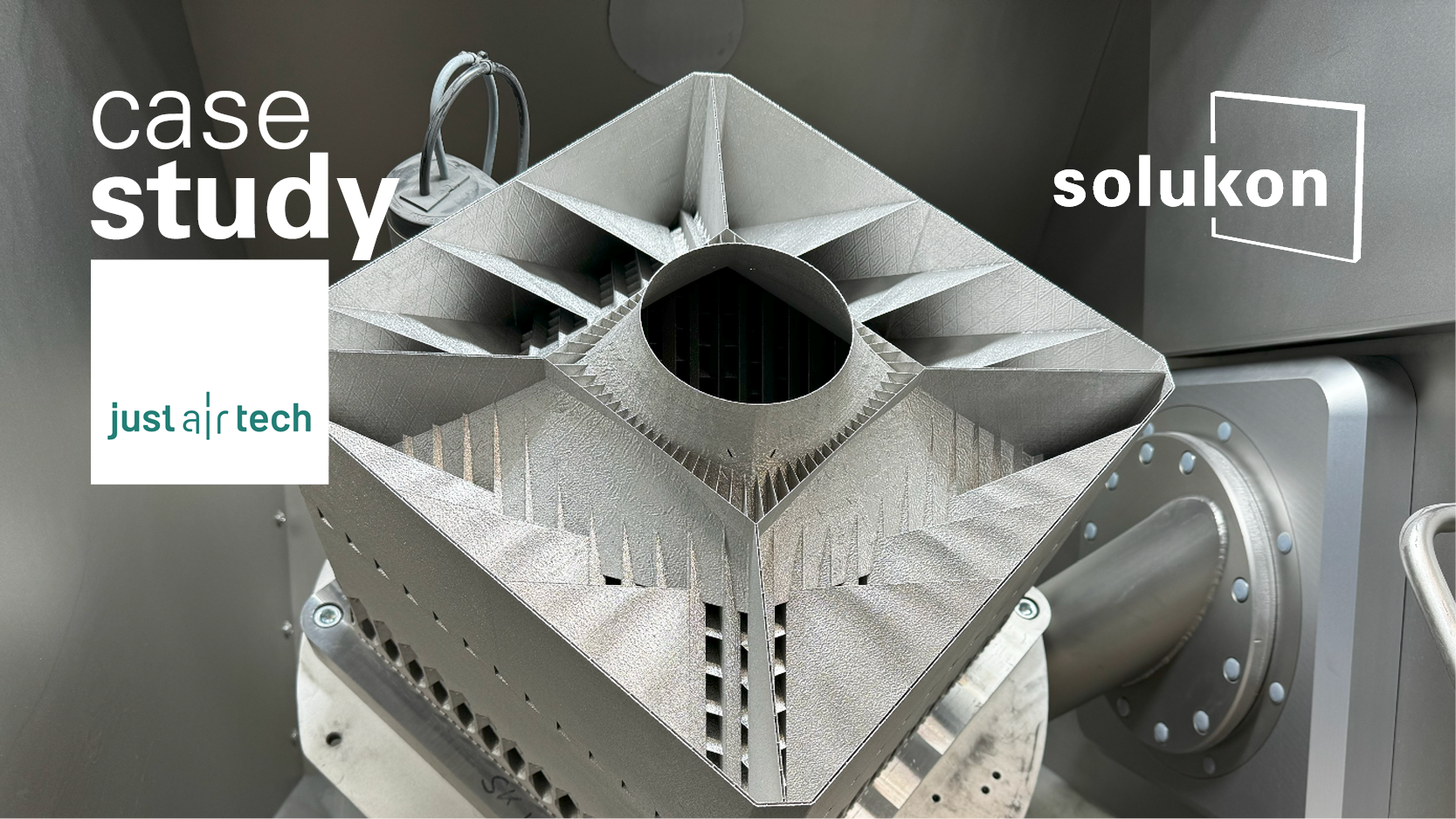

This case study features the automated depowdering process of a Heat Exchanger by company Enerbine.

Enerbine manufactures modular, fuel-agnostic inverter units designed for distributed power generation which are both compatible with liquid and gaseous fuels. Their technology combines cutting-edge 3D-metal printing with ceramic and advanced materials to deliver high precision, efficiency and durability. As an early adopter, Enerbine has been using SPR-Pathfinder® since installing the SFM-AT350 Solukon depowdering system at its plant.

In this case study, learn how Enerbine uses intelligent depowdering and how the company plans to further expand its depowdering capabilities.

FACTS & FIGURES ABOUT THE

APPLICATION AND DEPOWDERING PROCESS

| Build plate dimensions (W x D x H) | 200 x 200 x 350 mm |

| Printer | EOS M 400-4 |

| Material | In718 |

| Application | Heat Exchangers for power generation |

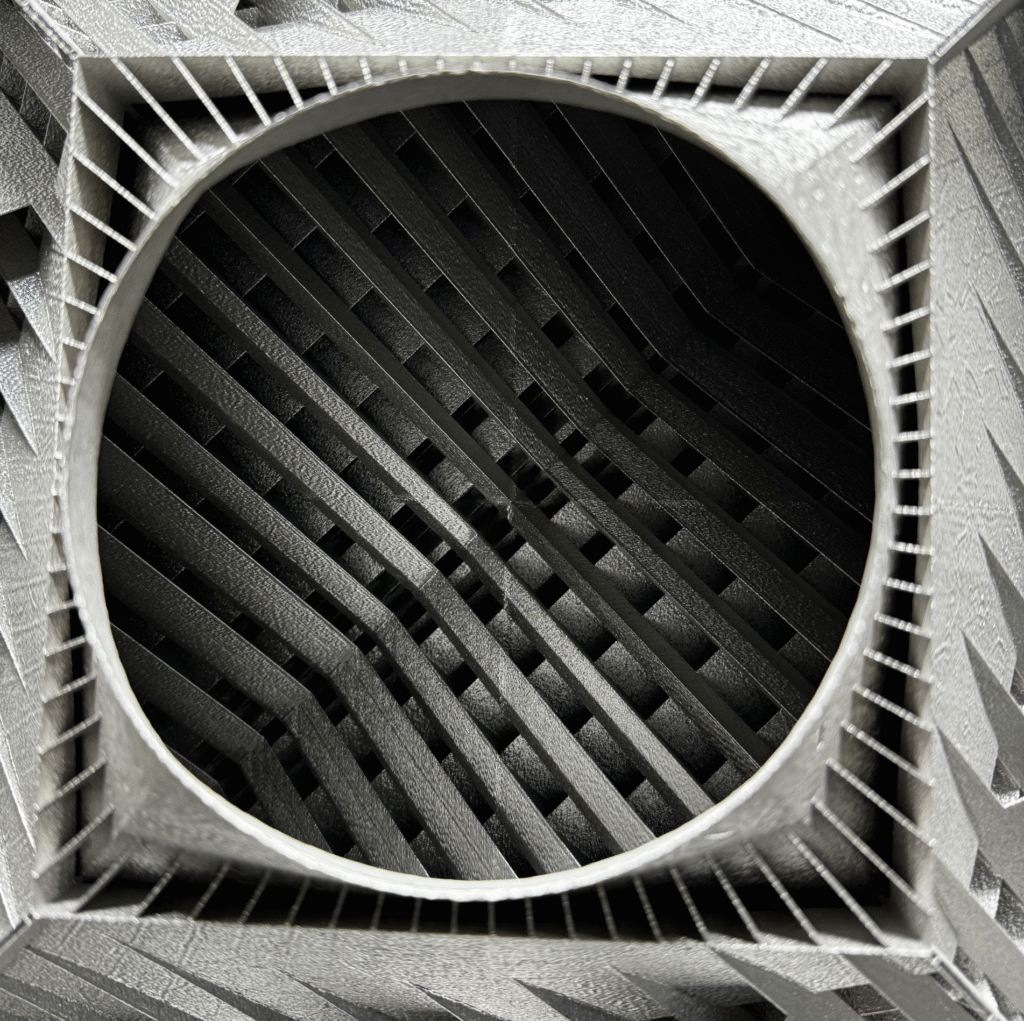

| Surface / structure | – Cylinder with thin walls and fuel injector inside – Curved channels inside the part which are approx. 200 mm tall in total – 4 parts of the same shape on one build plate |

| Smallest diameter of internal feature filled with powder | 0.2 mm |

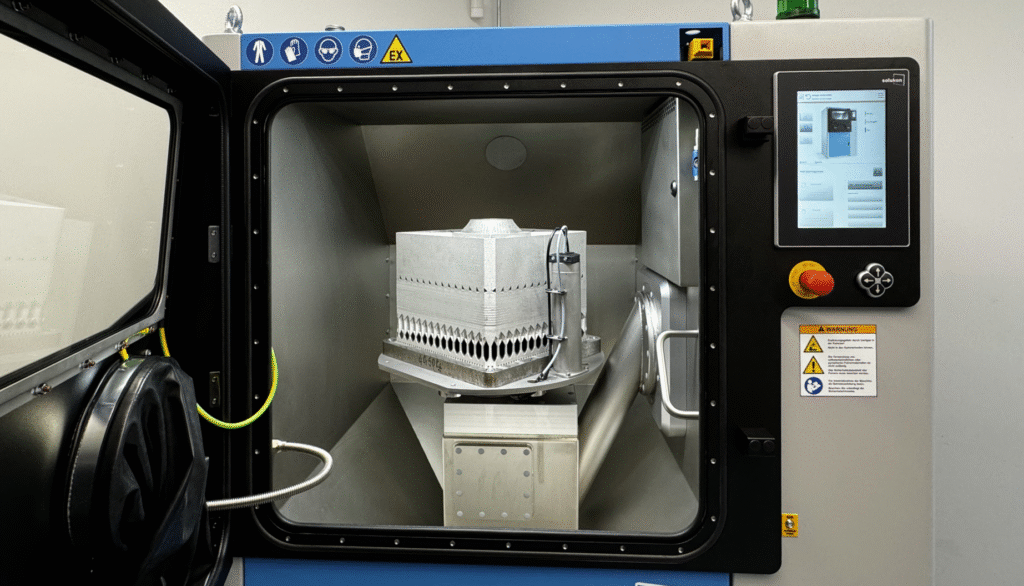

| Depowdering system | Solukon SFM-AT350 with high-frequent knocker |

| Duration of automated depowdering process | 360 min |

| Mode used | Intel Model with SPR-Pathfinder® |

| Number of cleaning steps | 1200 |

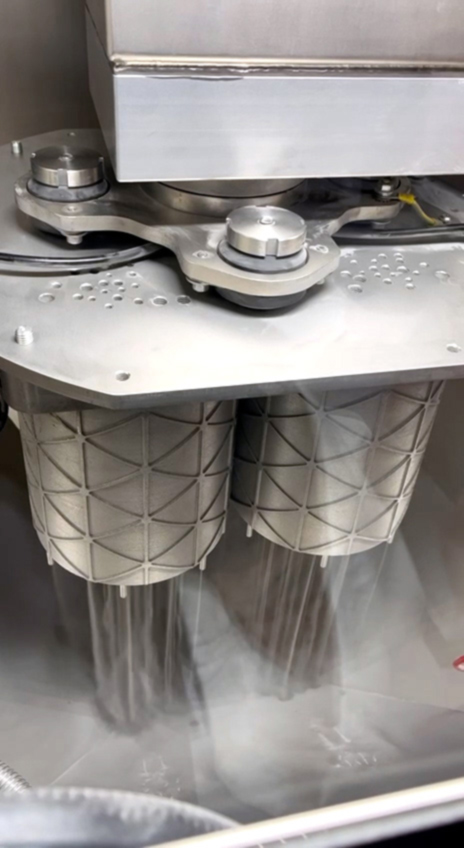

| Amount of recovered powder per cleaning cycle | 10-20 kg |

| How many parts of this type are depowdered? | 12 a week |

THE DEPOWDERING PROCESS

The depowdering process was carried out on the SFM-AT350 with a high-frequency knocker add-on.

During depowdering in Intel Mode with the SPR-Pathfinder®, a strong powder flow was detected. Targeted knocking helped loosen powder clogs in small part cavities (smallest size: 0.2 mm). Overall, the depowdering process for the heat exchangers in the SFM-AT350 took six hours. About 10-20 kg of powder could be collected for each depowdering cycle. Team Enerbine reuses the powder after sieving it for further printing processes.

After the depowdering process, Team Enerbine cut the parts open using an EDM. No powder residue was trapped inside the geometry. “Before we used the Solukon, powder was still trapped in the thin walls. Now, with the Solukon, only some dust remains on the walls”, says Erling LaSalle, Additive Manufacturing Engineer at Enerbine.

The depowdering process is followed by rinsing with IPA, heat treatment and machining.

SAFE PROCESS, LOW MAINTENANCE

Installing a Solukon depowdering system has significantly improved occupational health and safety because the powder is processed in a sealed atmosphere. The Solukon unit’s minimal maintenance requirements make it a valuable addition to Enerbine’s additive production facility, boosting efficiency.

THE ADVANTAGES OF DEPOWDERING WITH SPR-PATHFINDER® OVER CONVENTIONAL DEPOWDERING

Enerbine has found significant advantages in intelligent depowdering with SPR-Pathfinder®, which involves the precise precalculation of component movements based on the part geometry. Erling explains:

„Before we had the software, we set the program manually and ran it for 8 to 12 hours, but powder would still remain trapped inside the part. With the Pathfinder program, the process takes only 6 hours, and all the powder is completely removed.”

SPR-Pathfinder® is especially useful because the design of the heat exchanger is still being developed and changes slightly with each print. The software can quickly account for these minor changes to the component.

THE NEXT STAGE IN ENERBINE’S GROWTH IN INDUSTRIAL DEPOWDERING

Currently, the SFM-AT350 depowders up to four components on one build plate at a time. This will exceed the SFM-AT350’s maximum weight capacity soon, so Erling’s team plan to upgrade to the next largest Solukon depowdering system: the SFM-AT800-S. “We will need an SFM-AT800-S for full production setting”, Erling states.