SFM-AT1000-S

The pro-version ideal for extraordinary large parts with a height up to 1,000 mm

The SFM‑AT1000‑S is an automatic depowdering system for large and heavy metal components with a height of up to 1,000 mm and a maximum weight of 800 kg. This makes it the ideal postprocessing system for the aerospace & space industry. The SFM‑AT1000‑S depowders even the most complex rocket engines, which have internal cavities and channels, fully automatically and efficiently. The system is based on the unique Solukon Smart Powder Recuperation technology SPR®.

Optimized handling of various part sizes and intelligent motion

The SFM-AT1000-S has two endless rotating axes with programmable servo-drives so that it can move the part along any imaginable path. The system is available in a long-arm and a short-arm option for an optimized handling of parts with a special center of gravity. In addition, the SFM-AT1000-S is compatible with SPR-Pathfinder® software from serial number 1. The software automatically calculates the ideal motion sequence for each part, which is then read and executed by the Solukon system so that the powder is removed residual-free.

Safety and connectivity within the SFM-AT1000-S

After the automatic powder removal just use the sealed glove ports to manually remove powder residues with compressed air or inert gas. When working with reactive materials such as titanium or aluminum, you can use the system under inert condition. The recovered metal powder can be reused in further printing processes. Furthermore, the SFM-AT1000-S has an OPC UA interface for connectivity.

Advanced loading and handling of large parts

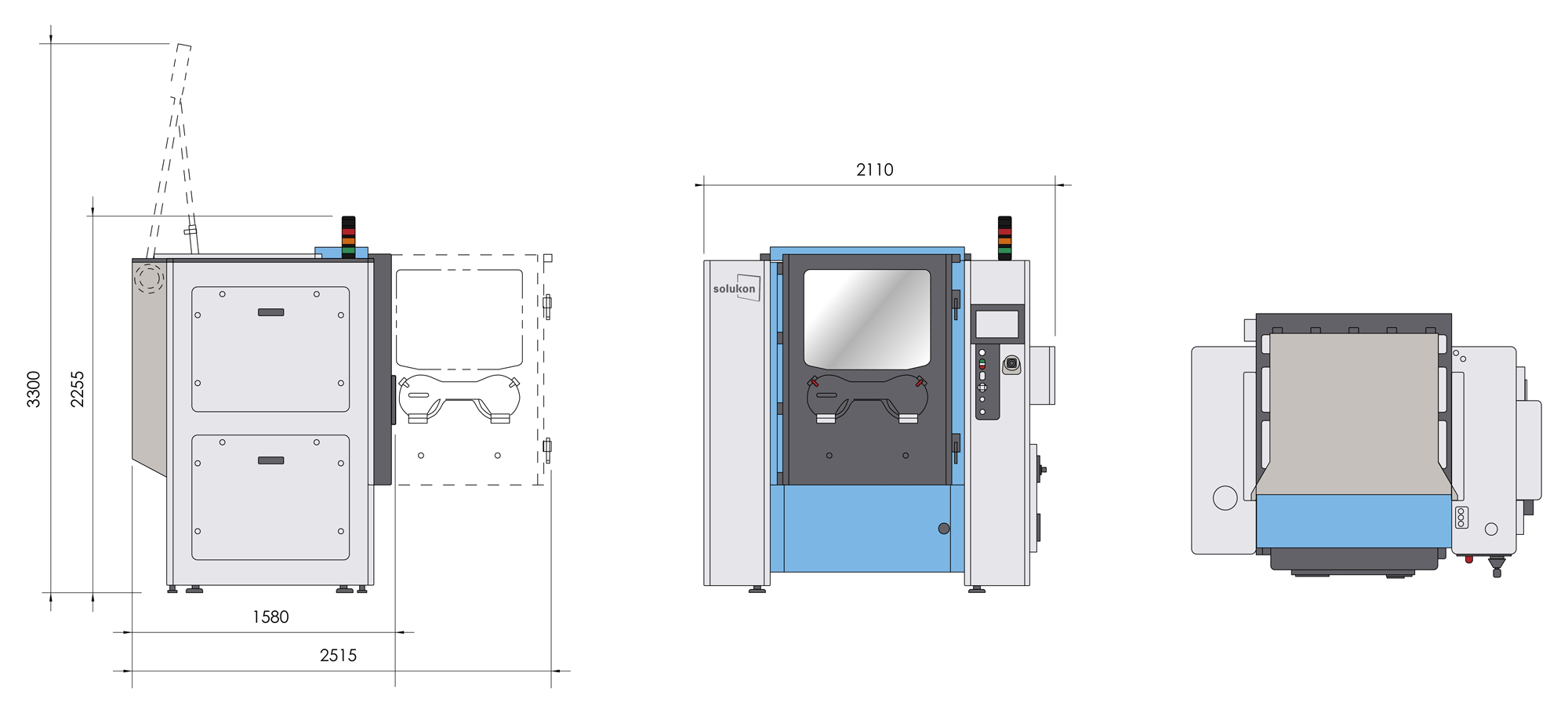

Front-top-loading of extra large parts is even easier with the new pneumatic opening roof and a front door that opens wider.

SFM-AT1000-S

The pro-version ideal for extraordinary large parts with a height up to 1,000 mm

SFM-AT1000-S

The pro-version ideal for extraordinary large parts with a height up to 1,000 mm

The SFM-AT1000-S is an automatic depowdering system for large and heavy metal components with a height of up to 1,000 mm and a maximum weight of 800 kg. This makes it the ideal postprocessing system for the aerospace & space industry. The SFM-AT1000-S depowders even the most complex rocket engines, which have internal cavities and channels, fully automatically and efficiently. The system is based on the unique Solukon Smart Powder Recuperation technology SPR®.

Optimized handling of various part sizes and intelligent motion

The SFM-AT1000-S has two endless rotating axes with programmable servo-drives so that it can move the part along any imaginable path. The system is available in a long-arm and a short-arm option for an optimized handling of parts with a special center of gravity. In addition, the SFM-AT1000-S is compatible with SPR-Pathfinder® software from serial number 1. The software automatically calculates the ideal motion sequence for each part, which is then read and executed by the Solukon system so that the powder is removed residual-free.

Safety and connectivity within the SFM-AT1000-S

After the automatic powder removal just use the sealed glove ports to manually remove powder residues with compressed air or inert gas. When working with reactive materials such as titanium or aluminum, you can use the system under inert condition. The recovered metal powder can be reused in further printing processes. Furthermore, the SFM-AT1000-S has an OPC UA interface for connectivity.

Advanced loading and handling of large parts

Front-top-loading of extra large parts is even easier with the new pneumatic opening roof and a front door that opens wider.

The depowdering of our 3D printed rocket engines is a big challenge, the parts are large and complex in their design, and so we required to find a solution that could help us to achieve this. Our Solukon machine, the SFM-AT1000-S, is perfect for the job and its processes help us remove all residual powder after printing takes place.

Product details

- automated, endless 2-axis rotation device

- vibration mechanism with wide frequency range

- glove ports for manual depowdering with compressed air or inert gas

- manual control via joystick

Contact

Simply fill out our contact form and we will get in touch with you.