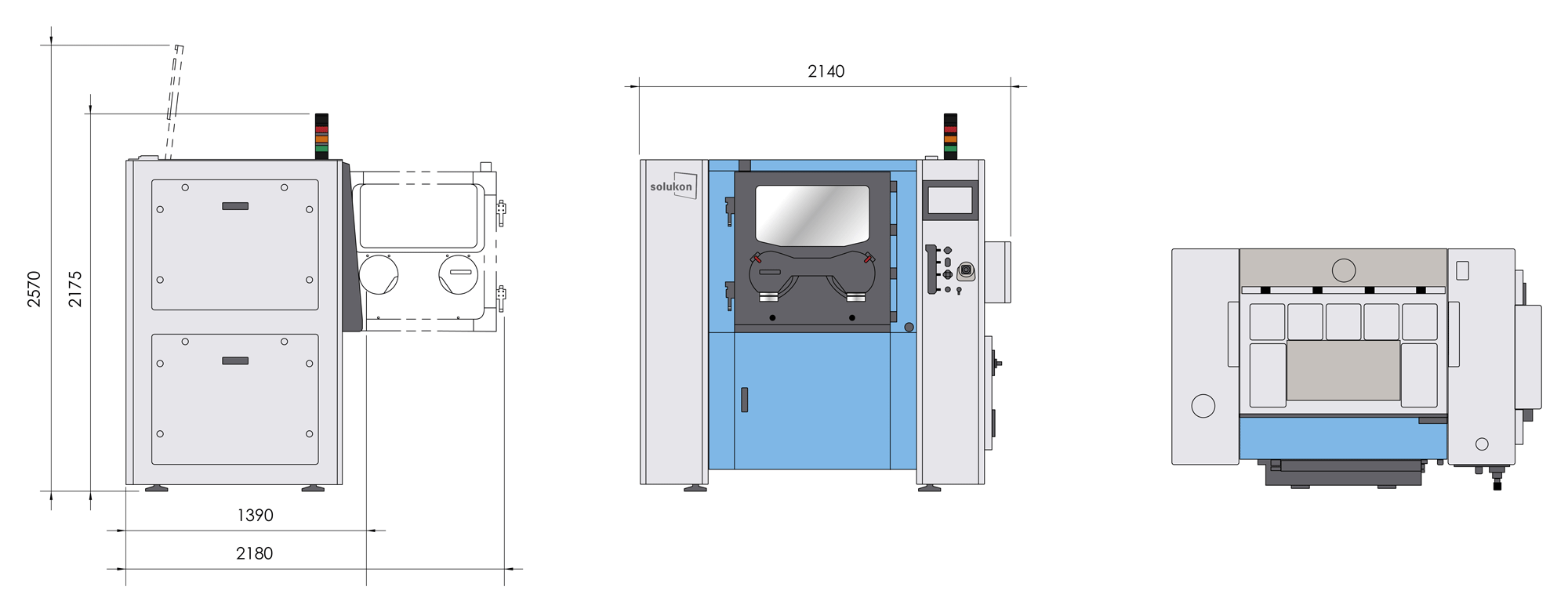

SFM-AT800-S

The award-winning flagship for complex geometries with a height up to 600 mm

The SFM-AT800-S is an automatic system for efficient depowdering of metal laser melted parts. It depowders parts with a height up to 600 mm and offers the industry’s highest standards of powder removal for large and complex parts with internal channels and hard to access geometries, such as heat exchangers. The postprocessing system uses the unique Solukon Smart Powder Recuperation technology SPR®. The SFM-AT800-S therefore cleans metal parts within a sealed process chamber using targeted vibration and automated programable endless rotation along two axes. Due to rotation of the parts unmelted build material can flow out of complex voids and support structures.

Programmable motion

The SFM-AT800-S is compatible with SPR-Pathfinder® software from serial number 1. The software automatically calculates the ideal motion sequence for each part, which is then read and executed by the Solukon system so that the powder is removed residual-free.

Safety and connectivity

After the automatic powder removal just use the sealed glove ports to manually clean with compressed air or inert gas. When working with reactive materials such as titanium or aluminum, you can use the system under inert condition. After the automated depowdering the metal powder is ready for reuse because it is free of any contamination.

In addition, the SFM-AT800-S is ready for robot loading or/and OPC-UA.

SFM-AT800-S

The award-winning flagship for complex geometries with a height up to 600 mm

SFM-AT800-S

The award-winning flagship for complex geometries with a height up to 600 mm

The SFM-AT800-S is an automatic system for efficient depowdering of metal laser melted parts. It depowders parts with a height up to 600 mm and offers the industry’s highest standards of powder removal for large and complex parts with internal channels and hard to access geometries, such as heat exchangers. The postprocessing system uses the unique Solukon Smart Powder Recuperation technology SPR®. The SFM-AT800-S therefore cleans metal parts within a sealed process chamber using targeted vibration and automated programable endless rotation along two axes. Due to rotation of the parts unmelted build material can flow out of complex voids and support structures.

Programmable motion

The SFM-AT800-S is compatible with SPR-Pathfinder® software from serial number 1. The software automatically calculates the ideal motion sequence for each part, which is then read and executed by the Solukon system so that the powder is removed residual-free.

Safety and connectivity

After the automatic powder removal just use the sealed glove ports to manually clean with compressed air or inert gas. When working with reactive materials such as titanium or aluminum, you can use the system under inert condition. After the automated depowdering the metal powder is ready for reuse because it is free of any contamination.

In addition, the SFM-AT800-S is ready for robot loading or/and OPC-UA.

The SFM-AT800-S is the ideal depowdering system for complex metal parts with internal channels. The programmable two-axis rotation offers our operators a unique range of possibilities

Product details

- automated endless 2-axis rotation device

- powder lock with special container

- vibration mechanism with wide frequency range

- glove ports for manual depowdering with compressed air or inert gas

- manual control via joystick

Contact

Simply fill out our contact form and we will get in touch with you.