Depowdering Metal

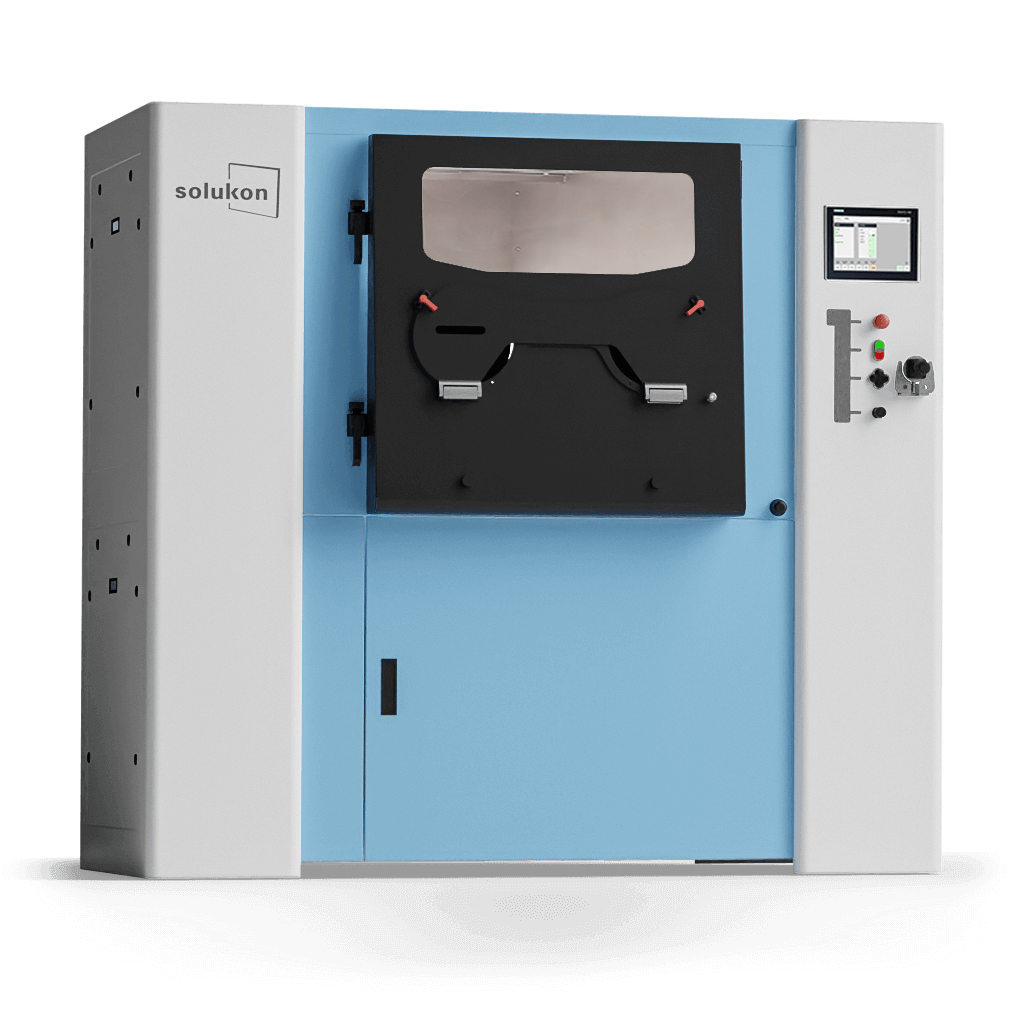

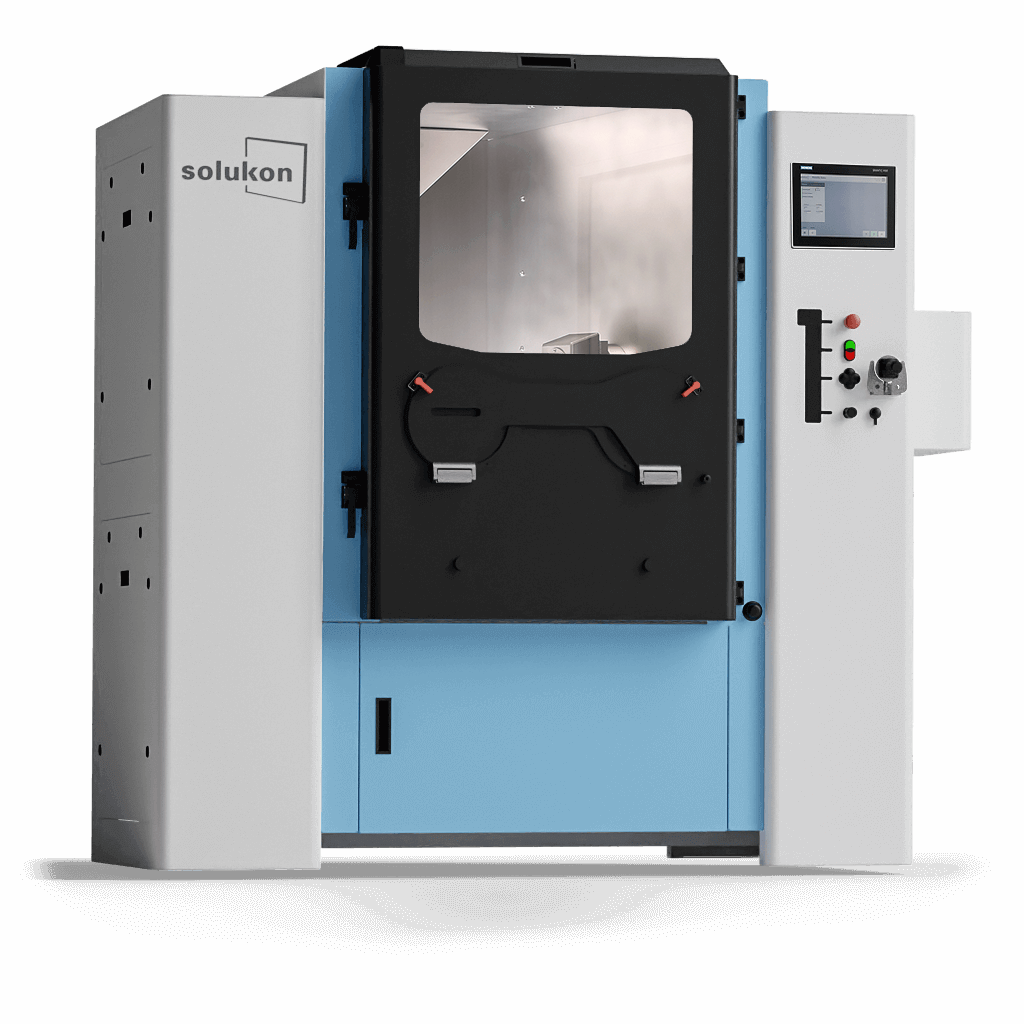

Solukon depowdering systems for metal components

Efficient postprocessing of metal laser melted parts with the Solukon Smart Powder Recuperation technology SPR®

Solukon offers a wide range of automatic powder removal systems for 3D printed parts. All systems are based on the unique Solukon Smart Powder Recuperation technology SPR®. Using (two-axis) rotation and targeted vibration, the cleaning units remove excess powder even from the finest internal channels of the component. Thus, Solukon postprocessing systems also depowder complex metal components like heat exchangers in a safe and efficient way. For reactive materials such as aluminum or titanium the powder removal units can run under inert condition.

Solukon is thus setting the highest standards for industrial depowdering in additive manufacturing.

The Solukon depowdering units are compatible with all additive manufacturing systems.

The post-processing systems mainly differ in terms of the part dimensions and the motion options of the swivel arms.

Advantages

Reproducible cleaning results

Time saving up to 90%

Approved explosion protection

High degree of protection from hazardous dusts

Residual powder retrival

Solukon Depowdering Systems in your AM production line

For a clean and lean production without any powder contact, you can also integrate the Solukon powder removal systems into your AM cell.

1. Depowdering

After unpacking the parts in the 3D printer, the depowdering station (here SFM-AT800-S) removes critical powder residues from the parts in a protected atmosphere and collects them contamination-free in the chamber bottom.

2. Sifting

The powder residue can then be fed to the powder recycling unit. There it is sieved and refreshed with fresh powder.

3. Reuse of powder

The powder is now ready for further printing processes.

Solukon’s powder removal systems thus ensure a closed, safe and efficient powder cycle in your AM production.

Contact

Simply fill out our contact form and we will get in touch with you.