SFM-AT800-S

Das preisgekrönte Flaggschiff für komplexe Bauteile

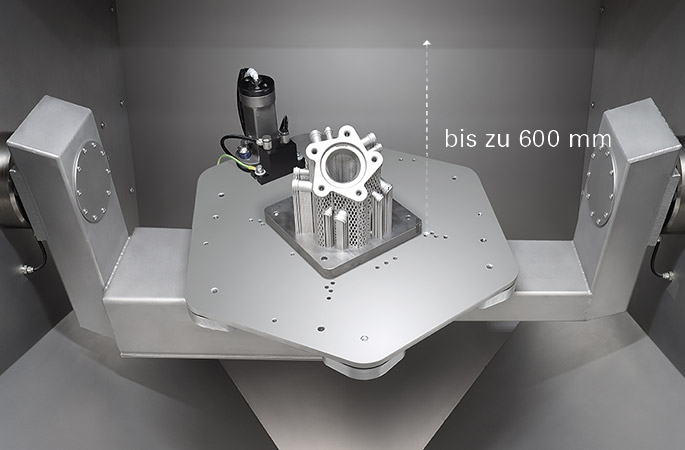

bis 600 mm Höhe

Die SFM-AT800-S ist ein automatisches Entpulverungssystem für komplexe Metallbauteile mit einer Höhe von bis zu 600 Millimetern. Die State of the Art Lösung der Pulverentfernung befreit auch komplexeste Bauteile mit innenliegenden Kanälen voll automatisch und effizient von Pulver. Das Postprocessing System basiert auf der einzigartigen Solukon Smart Powder Recuperation Technologie SPR®. Dabei wird rückständiges Pulver vollautomatisch aus komplexen Hohlräumen und Kanälen entfernt. Möglich macht dies eine programmierbare, endlose Bauteilrotation um zwei Achsen und Vibration innerhalb einer geschützten Atmosphäre.

Programmierbare Bewegungsmuster

Die SFM-AT800-S ist ab Seriennummer 1 mit der SPR-Pathfinder® Software kompatibel. Mit ihr lassen sich für jedes Bauteil individuelle Bewegungsmuster automatisch berechnen, die das Entpulverungssystem dann abfährt und so das Pulver restlos entfernt.

Sicherheit und Connectivity

Nach dem eigentlichen Reinigungsvorgang können Sie Pulverreste über Handschuheingriffe mit Inertgas oder Druckluft manuell abblasen. Wenn Sie reaktive Materialien wie Aluminium oder Titan entpulvern, kann das System inertisiert werden. Das rückgewonnene Metallpulver ist wiederverwendbar und steht für weitere Baujobs zur Verfügung.

Außerdem verfügt die SFM-AT800-S über eine OPC UA Schnittstelle und kann per Roboter beladen werden.

SFM-AT800-S

Das preisgekrönte Flaggschiff für komplexe Bauteile bis 600 mm Höhe

SFM-AT800-S

Das preisgekrönte Flaggschiff für komplexe Bauteile

bis 600 mm Höhe

Die SFM-AT800-S ist ein automatisches Entpulverungssystem für komplexe Metallbauteile mit einer Höhe von bis zu 600 Millimetern. Die State of the Art Lösung der Pulverentfernung befreit auch komplexeste Bauteile mit innenliegenden Kanälen voll automatisch und effizient von Pulver. Das Postprocessing System basiert auf der einzigartigen Solukon Smart Powder Recuperation Technologie SPR®. Dabei wird rückständiges Pulver vollautomatisch aus komplexen Hohlräumen und Kanälen entfernt. Möglich macht dies eine programmierbare, endlose Bauteilrotation um zwei Achsen und Vibration innerhalb einer geschützten Atmosphäre.

Programmierbare Bewegungsmuster

Die SFM-AT800-S ist ab Seriennummer 1 mit der SPR-Pathfinder® Software kompatibel. Mit ihr lassen sich für jedes Bauteil individuelle Bewegungsmuster automatisch berechnen, die das Entpulverungssystem dann abfährt und so das Pulver restlos entfernt.

Sicherheit und Connectivity

Nach dem eigentlichen Reinigungsvorgang können Sie Pulverreste über Handschuheingriffe mit Inertgas oder Druckluft manuell abblasen. Wenn Sie reaktive Materialien wie Aluminium oder Titan entpulvern, kann das System inertisiert werden. Das rückgewonnene Metallpulver ist wiederverwendbar und steht für weitere Baujobs zur Verfügung.

Außerdem verfügt die SFM-AT800-S über eine OPC UA Schnittstelle und kann per Roboter beladen werden.

Die SFM-AT800-S ist das ideale Entpulverungssystem für komplexe Metallteile mit innenliegenden Kanälen. Die programmierbare Zwei-Achs-Rotation bietet unseren Anwendern eine einzigartige Bandbreite an Möglichkeiten

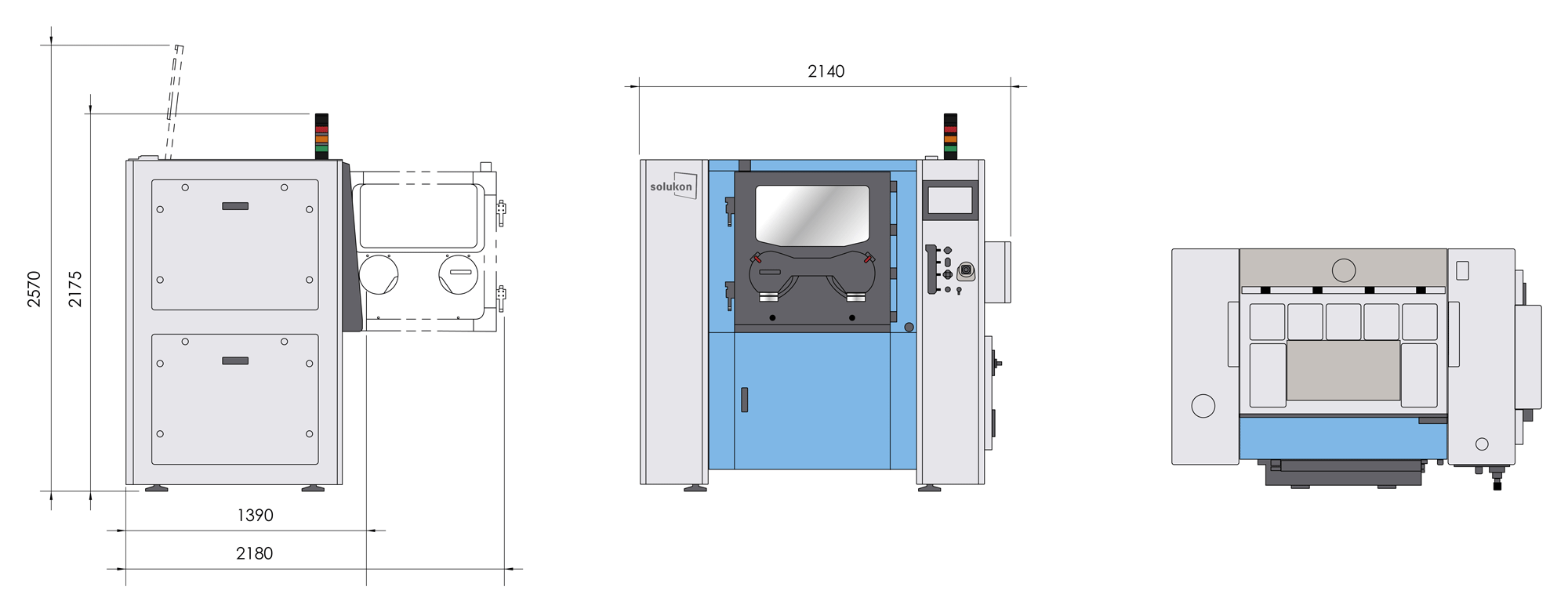

Produktdetails

- Automatisierte, endlose 2-Achs-Schwenkvorrichtung

- Materialschleuse mit Spezialgebinde zum Sammeln von Metallpulver

- Rüttler mit großem Frequenzbereich

- Manuelles Abblasen (mit Druckluft oder Inertgas) von Pulverresten über Handschuheingriffe

- Händische Steuerung mittels Joystick

Kontakt

Füllen Sie einfach das Kontaktformular aus und wir werden uns bei Ihnen melden.