Welcome to

Pioneer and technical leader

Your partner for efficient postprocessing in additive manufacturing

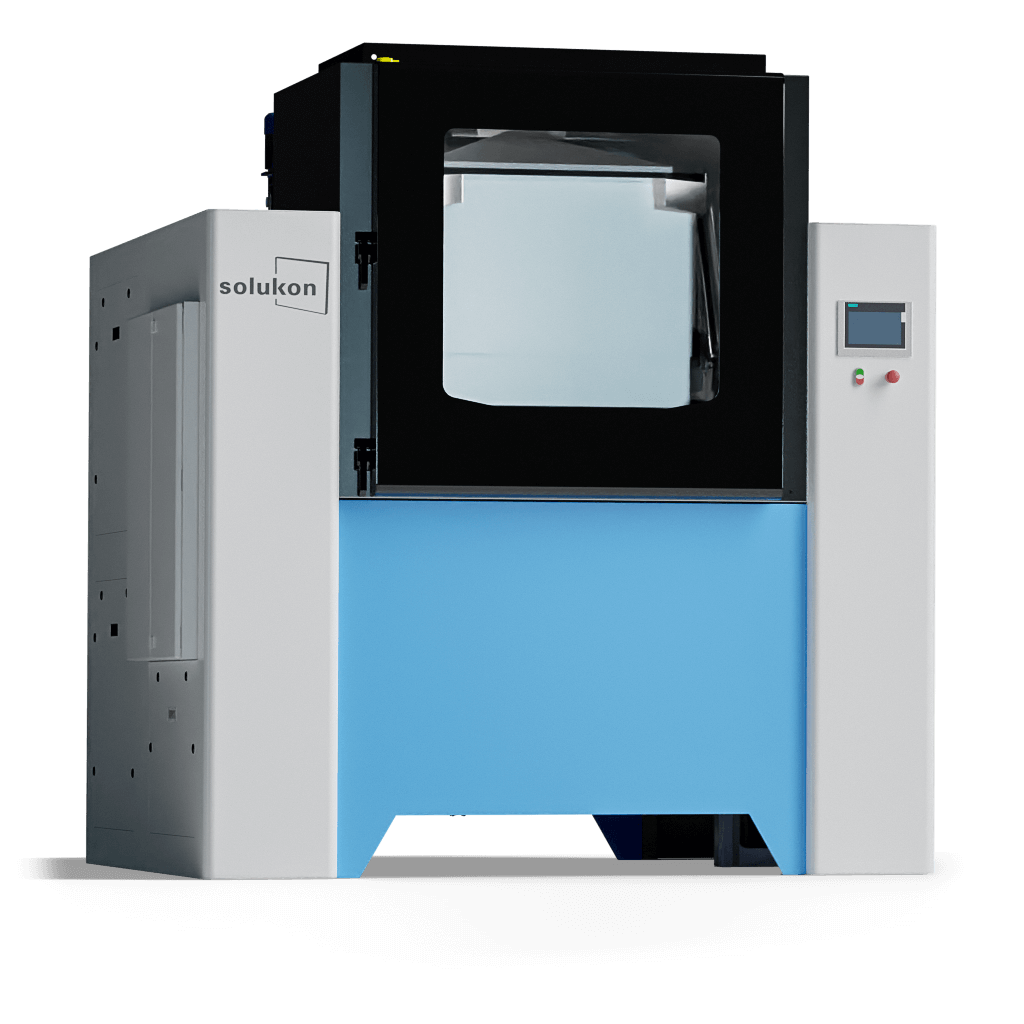

Solukon Maschinenbau GmbH is the leading supplier of depowdering systems for metal and polymer additive manufacturing.

The German company has extensive experience in the development of additive manufacturing systems and offers a full range of industrial powder removal systems. Solukon products meet the highest functionality and safety standards. Thus, Solukon is expert in powder removal of tough-to-handle material, e.g. copper. In addition, Solukon systems can handle reactive materials such as titanium and aluminum under safety controlled inert condition.

As pioneer and leading manufacturer in the field of industrial powder removal, Solukon not only manufactures the best depowdering equipment on the market, but also considers the digital integration of the equipment. Solukon is the first manufacturer in the world to offer a depowdering software, the SPR-Pathfinder®. It uses the build job’s CAD file to automatically calculate the motion sequence for the Solukon system to remove excess powder – so no human programming is required anymore.

Latest News

Depowdering of rocket parts: Stoke Space trusts in Solukon’s SPR® technology

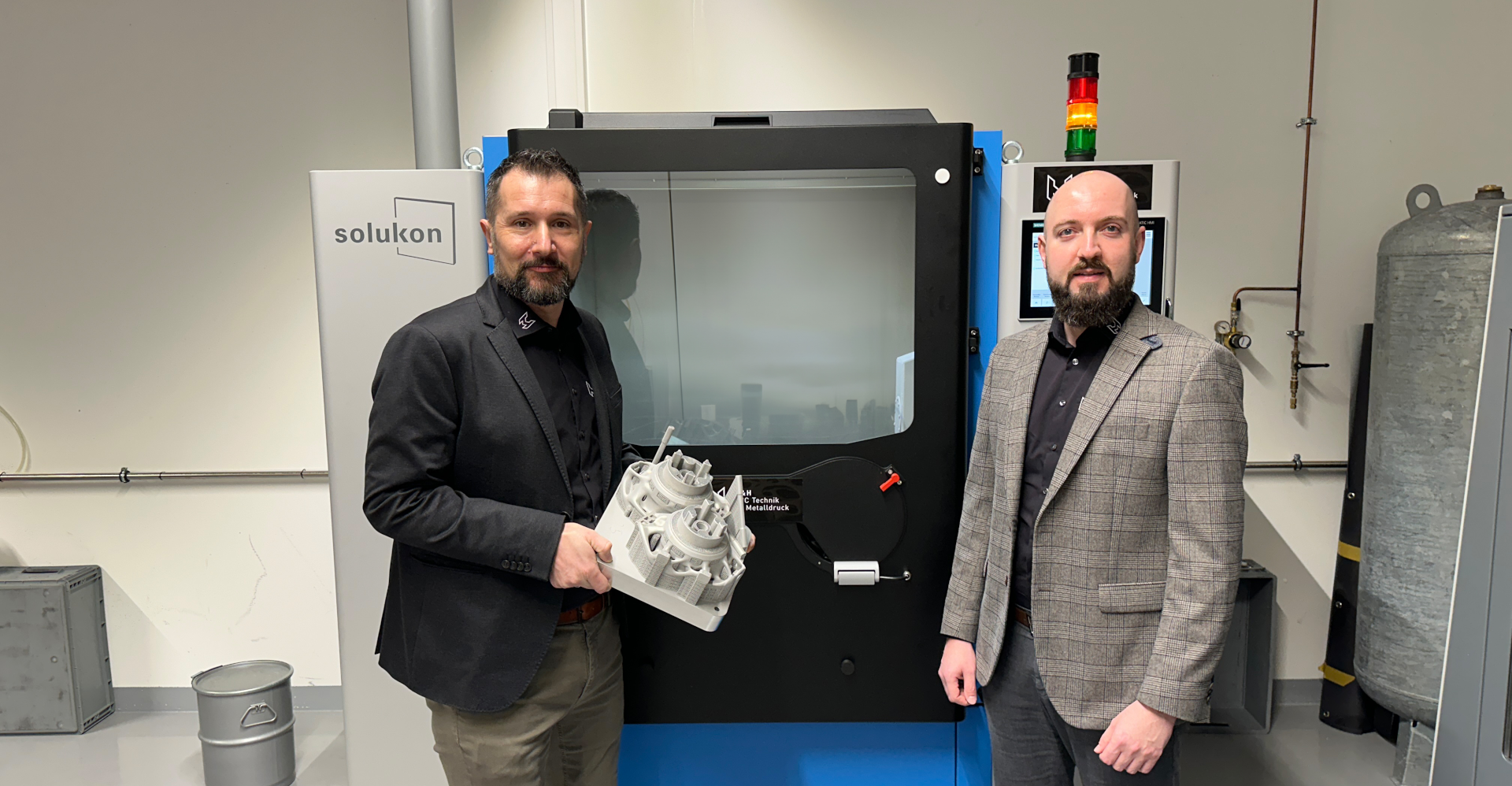

M&H relies on innovative depowdering system SFM-AT1000-S by Solukon

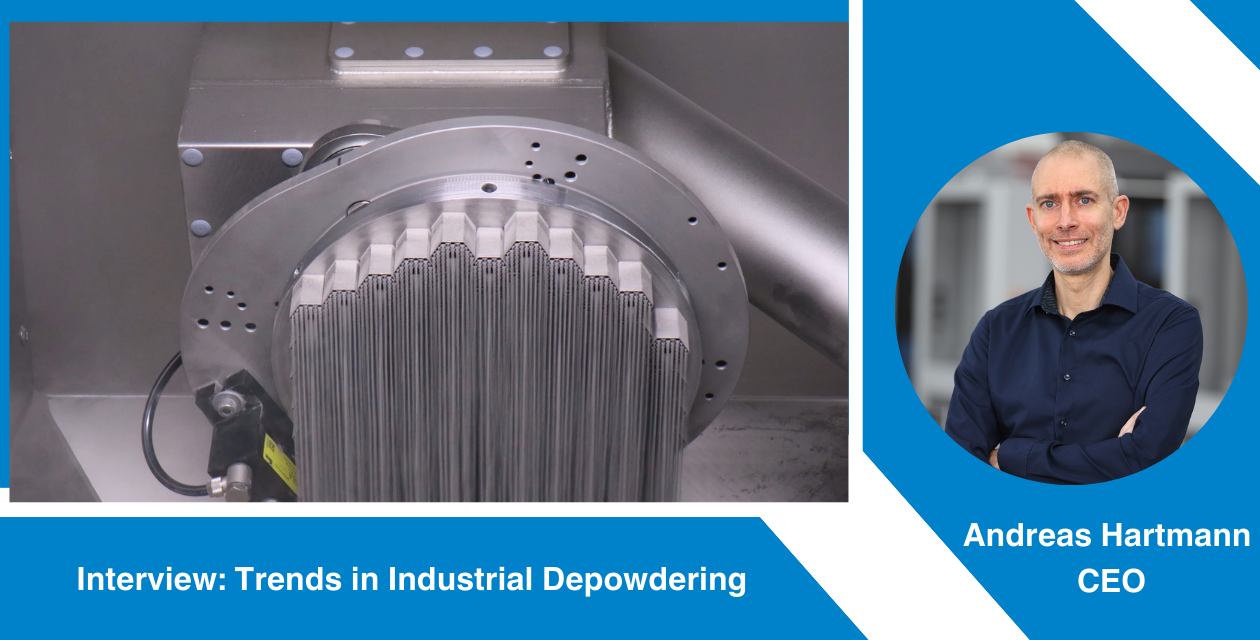

Digital integration, medical technology and opening up conventional manufacturing segments – current trends in automated depowdering

Home of Smart Powder Recuperation

With the introduction of the advanced Smart Powder Recuperation technology SPR®, Solukon developed the state of the art process for depowdering. Rotation and high frequent vibration ensure a fluidization of the powder. Leading manufacturers, like EOS, AMCM and SLM Solutions, companies like Lockheed Martin, Siemens and ArianeGroup and institutions like NASA trust in Solukon depowdering units.

Customers

Contact

Simply fill out our contact form and we will get in touch with you.