Automated depowdering – These are the trends in 2026

Automated powder removal has been an established part of industrial 3D printing for more than a decade. But what will 2026 bring? Which trends are already beginning to take shape? We look ahead.

KONTAKT

MARKETING@SOLUKON.DEAutomated powder removal has been an established part of industrial 3D printing for more than a decade. But what will 2026 bring? Which trends are already beginning to take shape? We look ahead.

Powder removal using ultrasound

Cleaning components with ultra-high-frequency excitation has established itself as an effective alternative to conventional pneumatic excitation. Around two years ago, Solukon introduced the first series-production system featuring ultrasonic excitation.

Delivering excellent cleaning results, including for customers such as justairtech and The Exploration Company, this new excitation method has clearly proven its value. As a result, interest in ultrasonic solutions continues to grow, with an increasing number of enquiries from the market.

These are the advantages of ultrasonic depowdering:

1. Particularly gentle cleaning

Piezoelectric excitation is applied directly to the turntable of the automated depowdering system, setting the component into optimal vibration with exceptional precision and minimal effort.

A key advantage of ultrasonic excitation is its variable frequency. Rather than operating at a single fixed frequency, the system continuously and rapidly cycles through a defined frequency range in which cleaning is most effective. This so-called sweeping process ensures highly reliable powder removal by targeting precisely controlled ultrasonic frequencies.

Because these ultra-high excitation frequencies are well above the component’s potentially harmful natural frequency, unwanted resonance is avoided. This prevents excessive vibration and protects the part from damage. As a result, automated ultrasonic depowdering is an especially gentle cleaning method, making it ideally suited for delicate structures such as lattice or sponge-like geometries used in medical technology.

2. Silent cleaning process

This can be a decisive advantage, particularly in otherwise noisy production environments: ultrasonic cleaning operates virtually silently.

3. Reliable loosening of powder clumps

Powder clumps may form inside components during the printing process as a result of moisture or insufficient excitation. This issue occurs most frequently in long, narrow internal channels. Ultrasonic excitation reliably breaks up and removes these clumps.

Depowdering software and even more automation

LPBF components are becoming increasingly complex, while a growing number of parts are moving into series production. Depowdering processes must keep pace with this evolution. Intelligent software that calculates the optimal movement sequence individually from the component’s CAD data enables reliable and repeatable depowdering which is an essential requirement for serial manufacturing and consistent cleaning quality. Software also allows cleanability to be assessed as early as the design phase, ensuring that complex geometries can be depowdered efficiently before production begins.

The rising demand for series production is closely linked to a growing need for further automation. In the field of depowdering, this opens up a range of customer-specific automation scenarios, including:

- Automated loading and unloading of parts

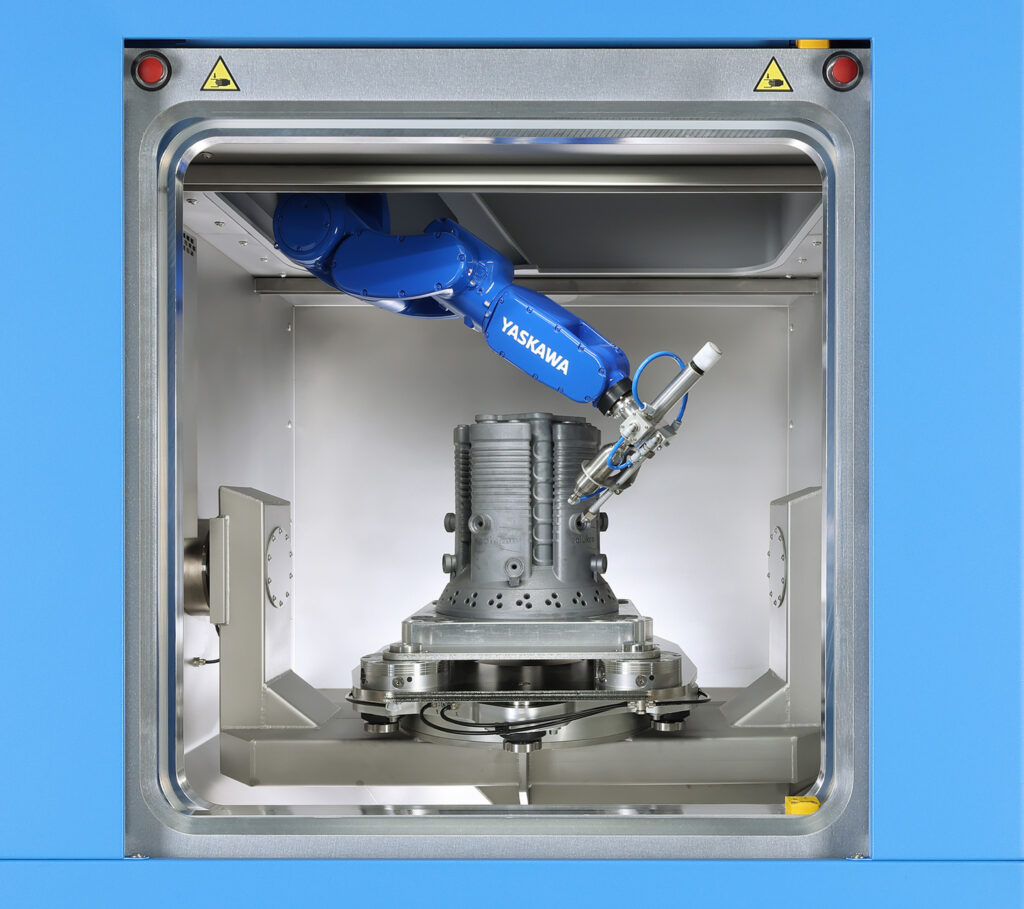

- Robot integration into the depowdering system, enabling tasks such as removing residual powder, performing cleanliness inspections, or applying targeted mechanical excitation to loosen powder deposits

Together, these trends point to an exciting year ahead for industrial depowdering in 2026.