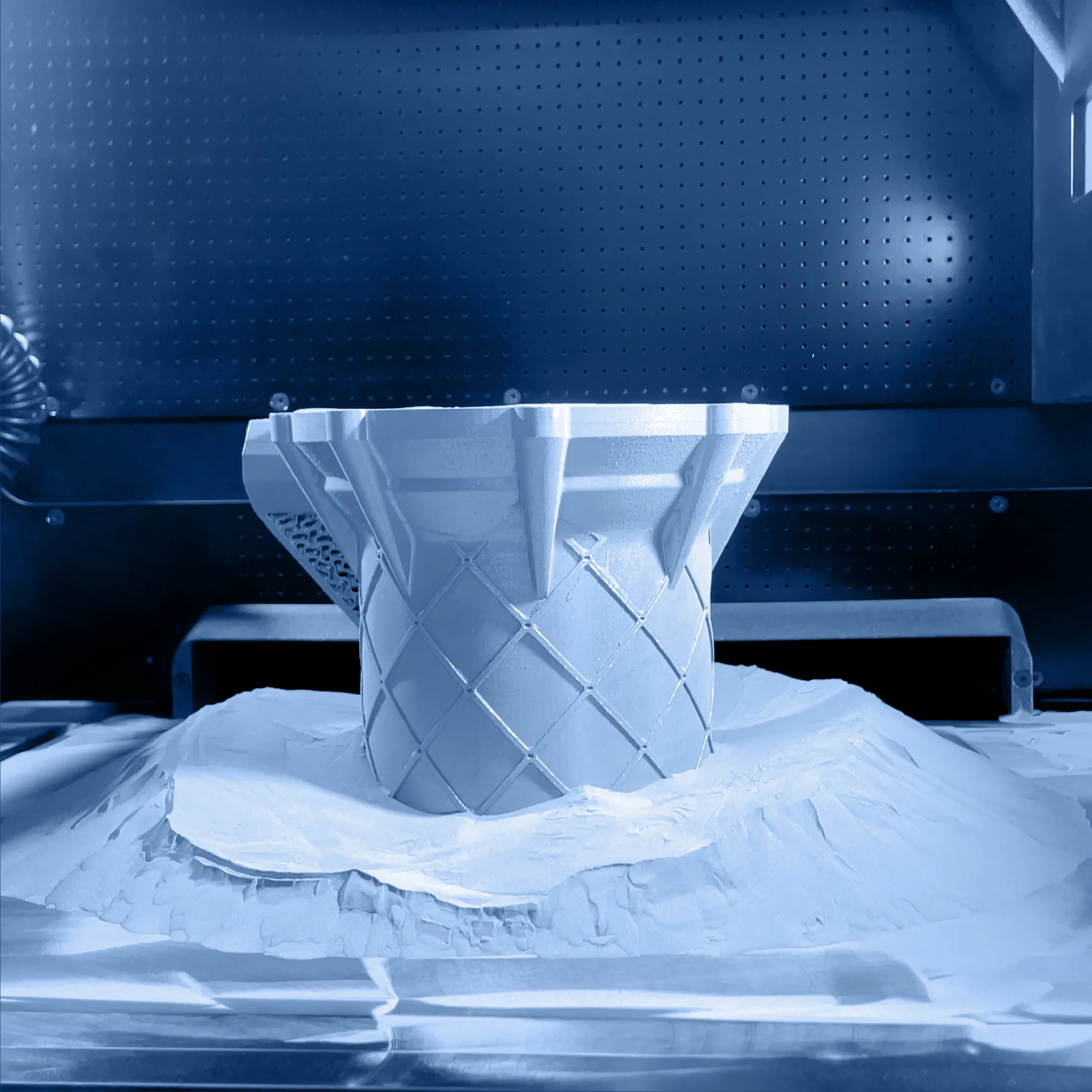

EFFICIENT DEPOWDERING OF LASER-MELTED METAL PARTS

Our depowdering systems are compatible with all 3D printers (LPBF) and can be inerted for reactive materials like titanium.

Choose your depowdering system based on the size and weight of your build job now and get efficient, safe and sustainable postprocessing.

OUR DEPOWDERING SYSTEMS

FOR METAL

WHAT MAKES OUR

DEPOWDERING SYSTEMS SPECIAL

Process monitoring and automation integration (DFT)

Unique depowdering software for calculation and simulation

Reliable, reproducible cleaning results

Intuitive handling (UX)

Numerous variable forms of excitation

Material- and customer-specific configurations

Easy integration into (automated production lines)

Compatible with all LPBF printers

Low-maintenance premium product with a long service life

Engineered and Made in Germany

Robust design in accordance with the highest industry standards

Patented technology

Technology of choice of leading AM companies

UL field evaluation approved

APPLICATIONS AND SECTORS

FOR OUR DEPOWDERING SYSTEMS

Solukon systems are used wherever 3D-printed parts must be cleaned efficiently and quickly. Classic industries like the energy sector, automotive industry and medical technology use them, as do industries of the future like the aerospace industry. Further, all the leading printer manufacturers (OEMs) put their trust in our technology.

provider

OEMs

IMPRESSIONS OF THE SOLUKON SYSTEMS